Cranes require thorough maintenance, servicing, and inspections. In addition to Work Health and Safety Regulations, all crane operators, providers, and teams exposed to crane operations on site must ensure work sites are safe, and that your staff are not exposed to health and safety risks while working. This includes the proper inspection and maintenance of cranes.

All routine crane inspections and tests must follow the crane manufacturer’s instructions. Even when a crane is not operated regularly, conducting routine inspections ensures no corrosion, damage, or deterioration has occurred to the machine while sitting idle.

How often should you inspect your cranes?

Routine mobile crane inspections should take place either weekly, monthly, or quarterly. A written report should be provided by the competent crane servicing provider that details the status and working condition of the crane, as well as identifying any parts that need replacing or any risks that have been observed that need to be mitigated before the crane is next operated.

To answer how often you need to inspect your cranes, we need to understand what type of crane is involved. Workplace safety regulations require operator licenses for various types of cranes, such as:

- Tower cranes

- Self-erecting cranes

- Derek cranes

- Portal boom cranes

- Bridge and gantry cranes

- Vehicle loading cranes

- Non-slewing mobile cranes

- Slewing mobile crane (for 20, 60, 100 & >100T tonnes)

A typical crane inspection should include:

- Crane functions and controls for speed, smoothness of operation, and limits of motion.

- Lubrication of any moving parts. Stress and friction are created anytime two moving parts come into contact.

- Emergency and safety switches and interlocks, including limiting and indicating devices.

- Verifying the accuracy of any load moment indicator (LMI) and rated capacity indicator (RCI) devices with a test lift using a certified test weight.

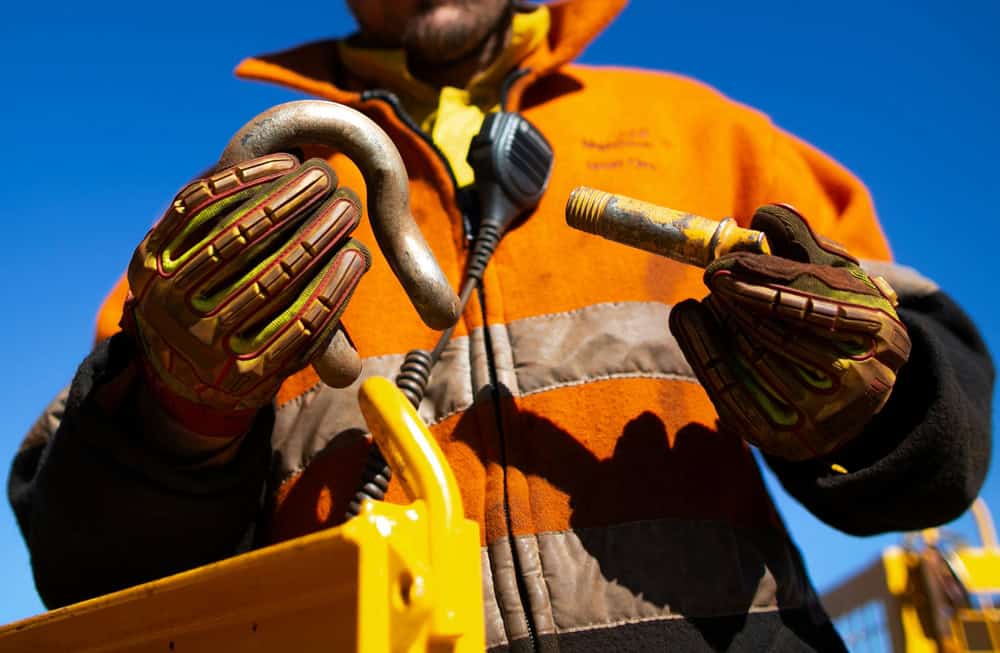

- Visual inspection and measurements of structural components and critical parts, including locking devices, gears, shafts, breaks, fasteners, sheaves, wire ropes, and electrical contractors.

- Wear on wheels and tyres.

- Filters and fluid levels and leaks.

- Signage, including warning signs and control markings.

- Extra items are nominated in the crane manufacturer’s instructions.

If there are any identified risks to health and safety, or if a hire mobile crane has suffered damage, it should not be operated on any construction site and be taken out of service. If the damaged crane needs to be operating during cleaning or maintenance, implement risk control measures to avoid compromising health and safety.

Pre-Use Checks

In addition to the programmed inspections and maintenance by qualified personnel, your crane operators should be trained to conduct daily pre-use checks to ensure the crane is safe.

Annual Crane Inspection

Every year, your cranes need a comprehensive crane inspection. Ensure this is conducted by a competent crane servicing provider. A thorough inspection will determine the crane’s condition and whether repairs or replacement parts are required. The annual inspection includes every item in the routine inspection and maintenance programs and items specified by the crane manufacturer for a yearly inspection.

Standard annual inspections should include detailed checking of the following:

- Functioning and calibration of limiting and indicating devices.

- Tolerances for wear limits.

- Critical areas for evidence of cracking.

- Structural and wear components.

- Evidence of corrosion; and,

- For tower cranes, you can safely complete the relevant items in the pre-erection inspection while the crane is erected.

Pre-emptively conduct annual inspections before erecting the crane or during the pre-erection inspection if the scheduled annual inspection falls on a date the mobile crane is booked for use.

Major Crane Inspection

It is a requirement that registered mobile and tower cranes undergo regular major inspections to ensure they pose no health and safety risks.

As stipulated by the manufacturer’s instructions, a competent servicing provider must perform major crane inspections at the end of the crane’s design life. This ensures these inspections meet the requirements established by relevant standards. Australian legislation requires major crane inspections to be undertaken at 10- and 25-year intervals throughout a crane’s working life.

These inspections require significant crane parts to be stripped for structural and mechanical inspection, repair, or replacement of critical parts, non-destructive testing and engineer certification.

Australian Standards & Codes of Practice

Where the regulations or manufacturer’s manual is silent on any aspect, consult the Australian Standards and Codes of Practice for guidance regarding safe use and compliance with the general duty of care.

Comply with health & safety regulations

We recommend brushing up on your knowledge of Western Australia’s health and safety regulations. This will stop your project from being subject to prosecution and ensure your team is acting safely to reduce injury or the risk of fatal errors. Rules and regulations evolve, so stay up to date with any changes. Crane operation typically requires special permits, so creating a checklist before you start to ensure you operate within the law is helpful.

Emergency plans

When operating heavy machinery, it’s essential to have an easy-to-follow emergency procedure plan in place.

- Ensure all team members are trained in the workplace emergency procedures

- Ensure they can identify where the muster point location

- Place emergency and contact numbers in easy-to-find places

Choose United Crane Services

With the United Crane Services team, we will help you get your job done right. Count on us for support, mobile crane hire services and emergency assistance. For more information, or if you’d like to speak with a heavy machinery specialist from a safe and reliable crane company in Perth, contact us at +61 08 9250 4488 today.